Construction joint systems

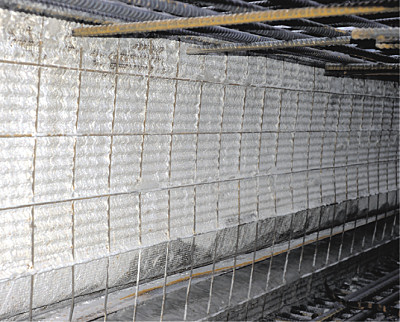

Shuttering elements with joint plate

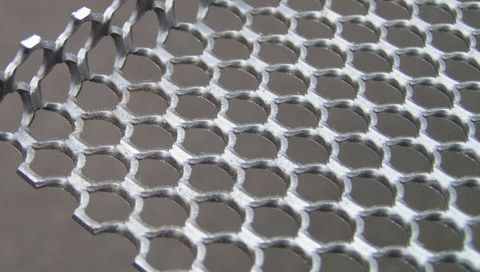

MSL construction joint shuttering elements with welded joint plate consist of corrugated profile perforated sheet metal or flat or trapezoidally profiled fine steel mesh.

Information

For over a decade corrugated profile MSL perforated steel elements with joint plate have been used successfully on building sites of all sizes all over the world. As steel prices have been increasing for years MSL added elements of the cheaper steel mesh with joint plate to its product range in early 2004.

The price benefit of steel mesh compared to perforated sheet metal is due e.g. to manufacturing a sqm of perforated sheet metal needing 1 sqm of continuous base material. Steel mesh, on the other hand, needs less base material as it is stretched to make the end product.

This is clear when considering 1 sqm of perforated sheet metal 0.5 mm thick with a spacing of 8 and an aperture diameter of 5 mm that weighs 2.35 kg/sqm. The aperture width in the perforated metal yields flow performance of about 36%. A sqm of rib mesh (steel mesh) 1.5 mm thick stretched to (E12 x 9.5 x 1.5) weights a mere 3.79 kg/sqm despite being three times as thick. Flow performance here is about 68%. Tests carried out by the University of Rostock's Institut fuer Bauingenieurwesen, chair of Building Design and Building Physics, showed that the shear load bearing capacity of MSL steel mesh elements is comparable to that of MSL perforated sheet metal elements.

Water impermeability testing of MSL construction joint shuttering with joint plate showed that corrugated profile MSL perforated sheet metal elements are superior to MSL steel mesh elements.

Both MSL steel mesh and MSL perforated sheet metal elements have proven themselves in practice.

In the field of water impermeability we recommend our corrugated perforated sheet metal elements as they offer greater safety. What's more these corrugated sheet metal elements greatly lengthen the water path in the construction joint area compared to flat steel mesh elements.